Introduction

Smart manufacturing represents the convergence of digital technologies with traditional manufacturing processes. At the heart of this transformation is physical artificial intelligence (AI), which integrates AI algorithms with physical systems, such as robotic arms, automated guided vehicles (AGV) and computer numerical control (CNC) machines. For these systems to be effective, they need real-time data from the physical environment – this is where sensors come in. Working as eyes and ears, industrial sensors have become indispensable in modern manufacturing and automation, transforming from basic measurement devices to sophisticated systems capable of detecting and monitoring various aspects of discrete and process automation. When paired with AI (vision AI, acoustic AI or physical AI), industrial sensors enable self-learning physical systems that improve manufacturing productivity, safety, digital twins and analytics.

This 2-part blog series is aimed at helping design engineers in selecting the right sensor products for their AI-enabled industrial applications. In this first blog, we will delve into various types of sensors and applications. The second blog will address the innovations in industrial sensors and the emerging trends in physical AI systems and smart manufacturing.

Understanding Industrial Sensors and How they work

Industrial sensors are devices that sense and process physical parameters such as distance, pressure, temperature, flow, level, motion, speed, acceleration and more. They collect data that is essential for monitoring and controlling manufacturing processes. This data is then sent to programmable logic controllers (PLC) or CNC through digital/analog I/O and communication modules.

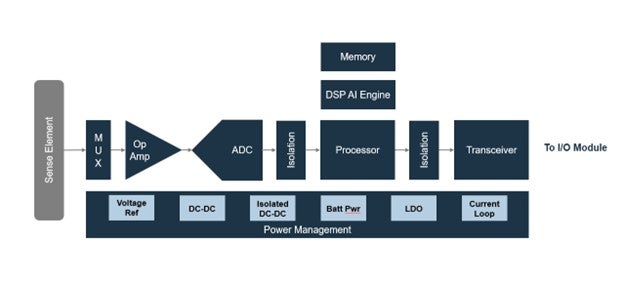

The primary components of a typical industrial sensor (see Figure 1) include a sensing element, voltage reference, operational amplifier (OpAmp), analog-to-digital converter (ADC), processor, interface, and power management. The sensing element measures a physical parameter and converts it into an electrical signal such as voltage, current, resistance and the like.

Industrial sensors act as the interface between AI and the physical world, much like the nervous system in a human body. When the digital world needs to interact with the physical environment, it needs these analog and mixed signal sensors. Next generation industrial automation systems not only include AI capability in the IT (Information Technology) cloud but also embed AI in the OT (Operational Technology) devices deployed in the field. This means AI algorithms are being used at the edge in sensors and PLC/robots to make rapid decisions. We will focus on sensors used in industrial automation here.

Types of Sensors

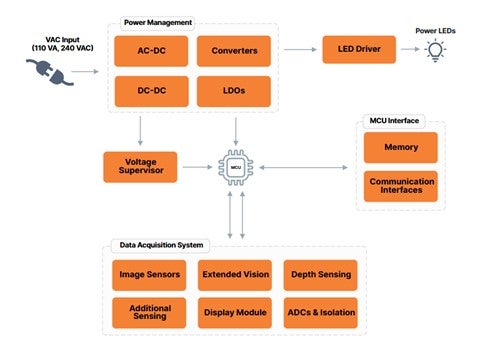

- Image (Vision) Sensors: Image sensors use cameras to capture images and videos of a product being manufactured to determine presence, orientation and accuracy. They are essential for quality control and inspection. These sensors can detect multiple points of a product with a single sensor and provide support for machine vision. onsemi’s image sensors and short-wave infrared cameras deliver excellent image quality at low power consumption. They offer high dynamic range and low-light performance to give your system the best results in any smart factory settings.

- Position & Torque Sensors: While Hall-effect, force, and optical sensors have been used for motor position control, these are very expensive when you consider the total solution with sense elements such as magnets or precision resistors or complex manufacturing for optical encoders. A new trend is using inductive position sensors that use PCBs with windings as sense elements with an AFE and controller in applications involving motion control and robotics. The NCS32100 and NCV77320 have unique advantages over traditional position sensors including but not limited to temperature tolerance, mechanical simplification and immunity to contaminants.

- Ultrasonic Sensors: Utilizing ultrasonic waves, these sensors measure distance. They are ideal for detecting transparent objects (unlike light sensors) and are unaffected by dust and dirt. A good example of a proximity sensor is onsemi’s NCV75215 that can detect objects from 25cm to 4.5m. In autonomous mobile robots, ultrasonic sensors are used for navigation and obstacle avoidance. Ultrasonic sensing technology can also be used for flow and level sensing of fluids in process automation applications, as well as detecting faults/cracks in quality inspection of finished products.

- Photoelectric Sensors: These sensors use light to detect objects. They are classified into thrubeam, retroreflective and diffuse-reflective types, each with unique features and applications. Photoelectric sensors are known for their non-contact detection, ability to detect almost all materials and support a long detecting distance with line of sight. They use infrared and laser technologies. A good reflective sensor example is onsemi’s simple QR1113, a 940nm infrared emitter encased side-by-side with a compatible silicon phototransistor in surface-mount and thru-hole packages.

- Proximity Sensors: These sensors detect metal objects without physical contact, using electromagnetic induction principles. They are highly resistant to environmental factors such as dust and oil. Ultrasonic and photoelectric technologies are preferred for non-metallic objects.

- Pressure Sensors: Pressure sensors are used in pneumatic, hydraulic, or clean room environments to maintain optimal operating conditions and alert deviations. They are typically based on strain gauges or force resistors configured in a Wheatstone bridge configuration to cancel out errors and measure the pressure in terms of small voltages.

- Temperature Sensors: Temperature sensors monitor and regulate temperature in various industries, from food processing to machine operation. Thermocouples and resistance temperature detectors (RTDs) are commonly used along with semiconductor temperature sensors such as onsemi’s ADM1023.

- Environmental Sensors: Environmental sensors like gas and chemical sensors monitor specific toxic or flammable gases in environments where vigilance is necessary. They are often integrated into safety systems. Rain and light sensors like the NCV76124 originally designed for automotive applications can send and measure reflected light using photodiodes to identify particulate matter in the environment. Or the CEM102 electrochemical sensor analog front-end used in continuous glucose monitoring (CGM) along with RSL15 Bluetooth® 5.2 enabled microcontroller can measure tiny changes in chemical current while operating at very low system power consumption.

Key Sensor Considerations

Here are the top 5 considerations when selecting the right sensors to enhance physical AI systems in smart manufacturing:

- Application-Specific Accuracy and Speed: Sensors must meet the precision and speed requirements of the specific AI task—whether it's real-time quality inspection, predictive maintenance or robotic control.

- Data Quality and Reliability: Sensors generate vast amounts of data over time that AI can analyze to uncover patterns. Sensors that provide repetitively reliable data are critical for training and running AI models to support agile decision-making across the manufacturing ecosystem.

- Interoperability and Integration: Sensors should seamlessly integrate with existing manufacturing systems and support standard field buses and communication protocols. This means new AI enabled sensors must be miniature and interoperate.

- Cybersecurity and Data Privacy: As networked sensors grow, so do the risks of cyber threats and demands on OT and IT security. Ensuring secure data transmission at the edge is critical, especially when AI systems rely on sensitive operational data from sensors for decision-making. This is achieved by self-calibrating and redundant sensors that can detect and isolate threats.

- Sustainability and Energy Efficiency: While expanding the number of sensors for physical AI, operators still need to be under the power budget and sensors that operate at low operating current provide an advantage for scalability.

In conclusion, industrial sensors are the fundamental building blocks that enable physical AI systems to perceive, understand and interact with the real world both at the edge and cloud. As AI continues to evolve, advancements in sensor technology will be crucial for unlocking its full potential and developing more intelligent and adaptive systems in smart manufacturing. onsemi has taken a leadership position in intelligent sensing technologies. With its broad sensor portfolios and application expertise, onsemi is at the forefront to help its customers transition into Industry 5.0. Stay tuned for our part 2 blog where we will continue with sensor innovations and future trends.

Additional resources: