Previously we looked at how industrial sensors work as the nervous system of physical AI systems in smart manufacturing. They provide the data needed for machine learning models to make autonomous decisions. Real-time feedback loops enabled by sensors allow machines to adapt to changing conditions and optimize performance. In this second blog, we will delve into how industrial sensors evolve and power physical AI in smart manufacturing.

Industry 4.0 and IoT trends have resulted in an explosion of intelligent sensors for productivity, safety and predictive maintenance in addition to providing data to make intelligent decisions on quality, factory upgrades and production forecast. Instead of sensors that just measure and send data to a controller for decision-making, new sensors can determine on improving latency and factory throughput. In addition, Industry 5.0 or smart manufacturing is making a significant shift towards a human-centric approach driving expansion of safety sensors to enable co-working of humans and robots as well as environmental sensors that reduce negative climate impact of factories on societies.

Sensor Innovations

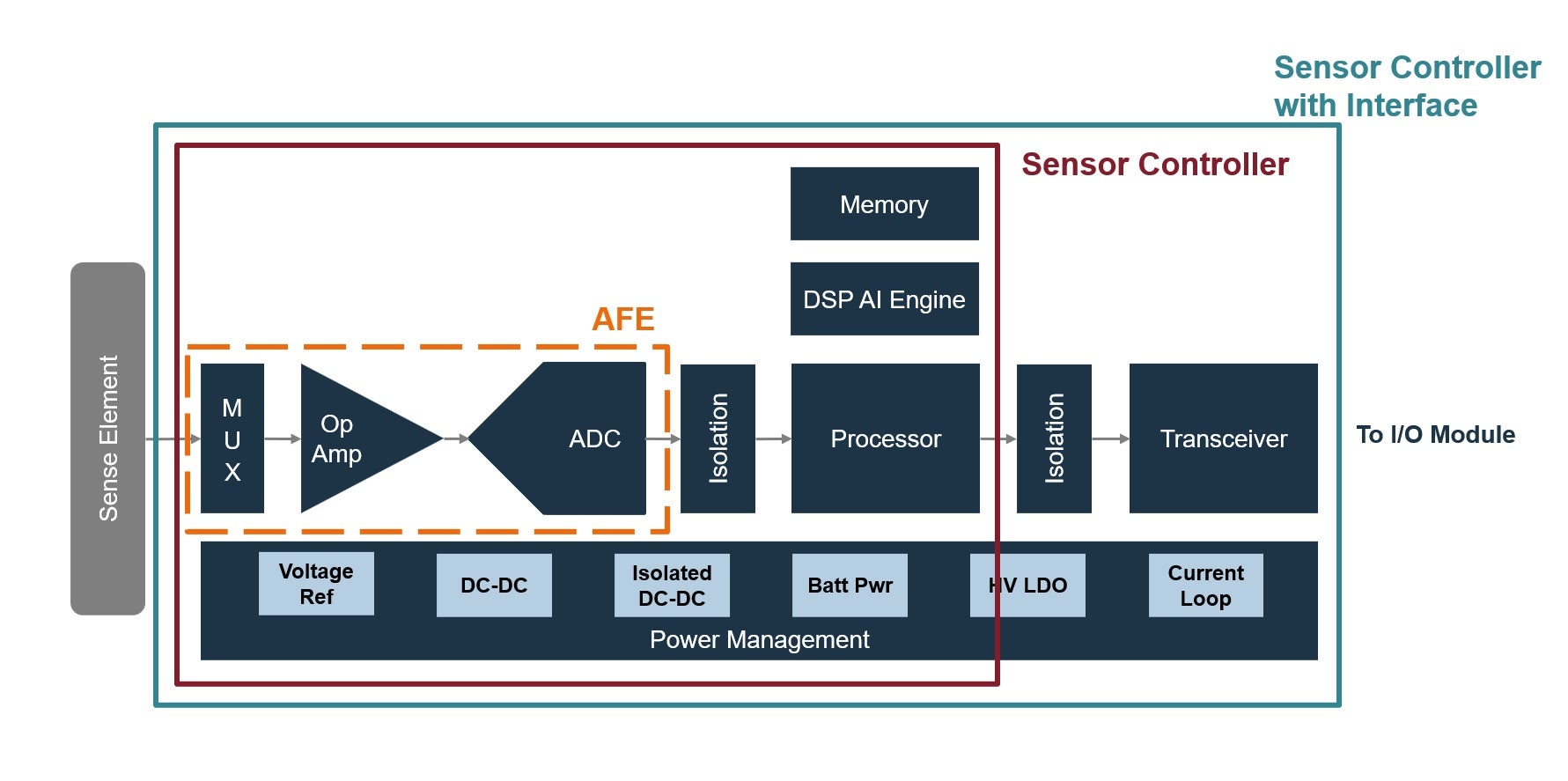

To build a sensor, system designers would use an off-the-shelf IC for each of operational amplifier (Op-Amp), voltage reference, analog-to-digital converter (ADC), power management, central processor unit (CPU), interface and system functions that work with the sense element to digitize the analog signal, process and connect with I/O modules to send the data to a programmable logic controller (PLC). Sensors in process automation may also need optional galvanic isolation in some applications between the ADC and CPU, and between CPU and interface.

IC vendors integrated application-specific analog and mixed signal blocks into a single chip that includes Op-Amp, voltage reference, ADC and power management, calling it a sensor analog front end (AFE) (see figure 1) to enable low latency, better accuracy, size and ease of use.

New sensing technologies, production throughput and ability to make independent single sensor and collaborative multi-sensor decision making without the need for a controller have pushed the needs for higher precision AFE/ADC and micro-controllers in sensors. The desire to enable power and data on the same wire or wirelessly has forced OEMs to adopt new interface standards. Finally, AI/ML presents remarkable opportunities that customers are interested in, but do not know how to exploit.

The new advanced BCD (Bipolar CMOS DMOS) processes below 90 nm that combine high-density and high-speed digital logic as well as high power, high precision analog on the same IC, are opening doors for fully integrated sensor controllers to go beyond a sensor AFE and even integrate processors into a single chip. The Treo Platform is a good example of such a process. Moving down to lower semiconductor process geometries results in lower gate voltages. Unlike other vendors that use low 1.8 V gate drive voltage for analog blocks in 180 nm and below processes that require use of large noise decoupling circuitry on the chip that blows up the IC die size, onsemi deliberately designed 3.3 V gate drive for analog circuits and 1.2 V for digital logic gates getting the best density, performance and precision for mixed signal ICs, without noise and long term reliability issues.

Future Trends in Industrial Sensors

Just as Industry 4.0 added digitalization, cloud analytics and intelligence to sensors, Industry 5.0 is about interaction between humans and machines alongside each other on the factory floor that is being made possible by AI-enabled sensors. Unlike machine vision sensors that need external high-end 25 TOPS (Tera Operations Per Second) edge AI processors, all other types of sensors need built-in AI and digital signal processing (DSP) accelerator engines inside the sensor controller chips.

Here are some examples of sensor controllers:

- NCS32100 Inductive Position: The NCS32100 offers a full featured controller and sensor interface for high resolution high accuracy angular sensing when paired with a printed circuit board sensor element. The NCS32100 has flexible configuration capabilities allowing connection to a variety of inductive sensor patterns and offers a variety of digital output formats. Inductive sensing techniques offer unique advantages over traditional position sensor solutions, including but not limited to temperature tolerance, mechanical simplification and immunity to contaminants. This inductive position sensor controller provides high-resolution, high-accuracy angular sensing solutions for rotary motor encoders by using adaptive learning algorithms in the on-board DSP engine challenging currently used optical encoders. It features programmable index, temperature and battery measurements and supports connection to an external RS-485 driver. The NCS32100 is ideal for industrial automation, robotics, motor control and servo applications.

- NCV75215 Ultrasonic: Our ultrasonic sensor controller can be used for detecting proximity, presence, flow, concentration, leakage, pressure, temperature and level. They offer non-contact detection, high resolution and the ability to measure in challenging environments. This is made possible by built-in accelerator engine. The controller also excels in sensor cleaning (ultrasonic lens cleaning) and Acoustic AI sensing. They are ideal for applications in industrial automation, environment navigation, process control, medical and non-destructive testing

Industrial sensors are at the forefront of the manufacturing automation revolution as they drive productivity and efficiency while supporting sustainability, safety and quality across various industries. New mixed-signal semiconductor processes such as the onsemi Treo Platform are enabling integration of high speed digital processing with high-performance analog functionality into a single chip. Our innovative sensor products using inductive, ultrasonic, image, pressure, biochemical and other technologies, range from sensor AFEs to sensor controllers and AI-enabled sensor controllers to meet the demands of modern industrial applications, providing accurate and reliable measurements and adapting (AI/ML) to changing operating conditions.

onsemi’s role is to continue to provide sensor-driven innovation and embrace the AI to stay ahead in the world of smart manufacturing.

Additional resources: