Permanent magnets are vital components in an enormous number of domestic and industrial devices. They are particularly crucial within the renewable energy sector, including the motors for electric vehicles. Currently, these magnets are based on the rare earth elements neodymium and dysprosium, which are becoming increasingly more expensive for use in electric vehicle motor design. The EU has begun objectives to remove, or greatly reduce, the need for heavy rare earths in permanent magnets. They are researching several novel microstructural-engineering strategies that will dramatically improve the properties of magnets based purely on light rare earths elements.

Currently, high power density electric machines for electric vehicles rely heavily on using rare earth material based permanent magnet motors. With the ever-increasing cost, restrictions and scarcity of rare earth magnetic materials, the industry is beginning to react to this problem from a new direction. Until inexpensive engineered magnetic materials exist, alternative machine types may provide suitable solutions. Both the induction machine and the separately wound rotor machine, are becoming attractive alternatives for EV electric machines.

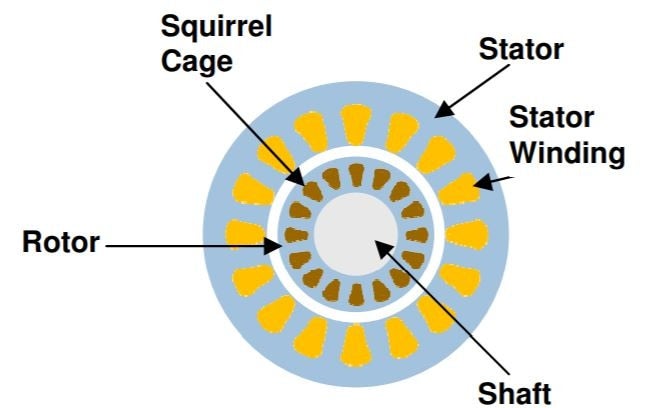

Figure 1. Induction Machine

The Induction Machine (IM) is one magnet-free choice, which has long been popular for some EV manufacturers, as an alternative to PM machines. The IM is used for its reliability, favorable fault modes and wide range of efficiencies. The typical EV induction machine is quite simple and consists of a wound three-phase stator and a squirrel cage rotor, as shown in Figure 1. Its operation is quite simple when the stator winding is energized with a three-phase voltage, it causes a current which builds up a magnetic field. The stator rotary field induces voltage into the squirrel cage of the rotor. The induced voltage of the rotor causes current and torque. The rotary field of the stator interacts with the rotary field of the rotor. This results in torque which rotates the motor shaft. The IM performance has been optimized for use in EV’s by Tesla’s with a proprietary rotor design, fabricated with copper.

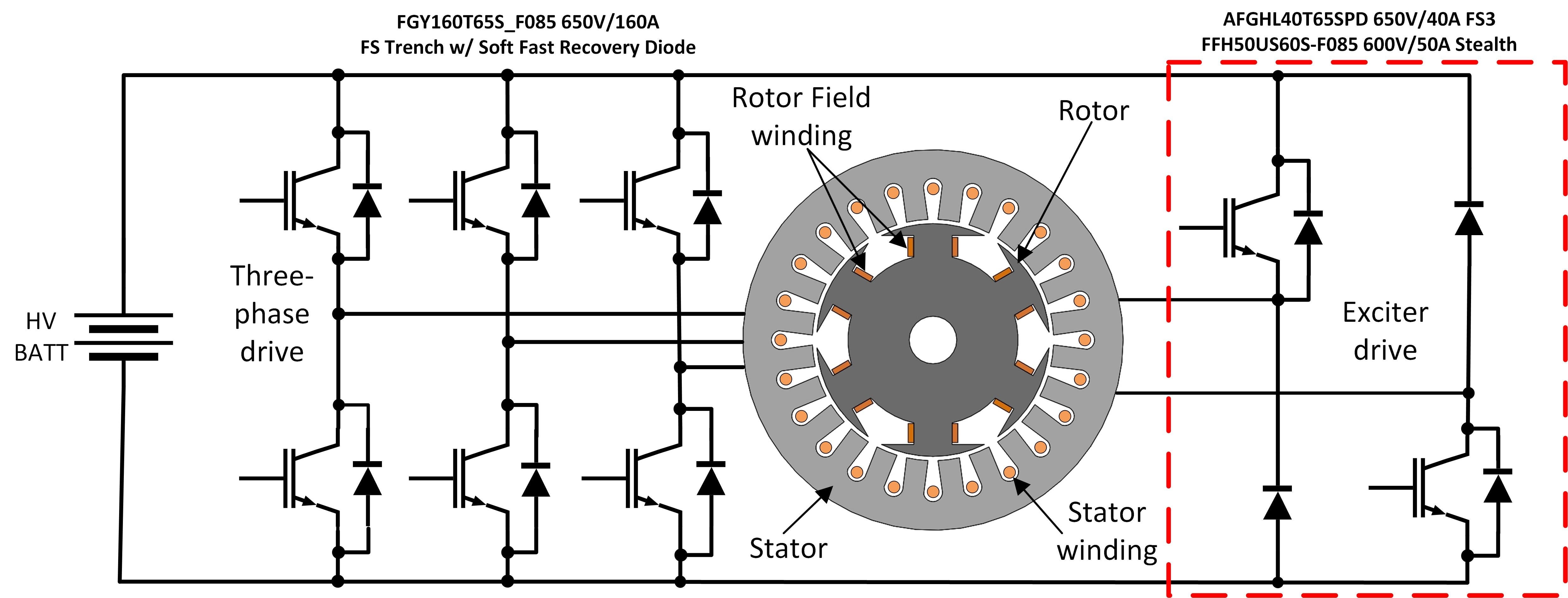

Figure 2. Seperately Excited Sync. Drive

One alternative EV motor design choice has recently appeared, it is the Separately Excited Synchronous Machine (SESM). Its schematic diagram is shown in Figure 2. This new EV motor technology, which has been common in industrial systems for many years, is proposed as an alternative to the PM and IM machine choices. This machine consists of a wound three-phase stator and a wound single-phase rotor. The rotor is energized by the use of a pair of slip rings, which are undesirable due to reliability concerns. However, in this configuration, the rotor flux can be directly controlled, which gives it a great advantage in its control ability. The PM machine is designed with large magnetic flux to meet low-speed, high torque demands. This large flux becomes undesirable at high speeds and must be reduced through the use of field weakening. This is a method where the stator creates a counter field to reduce the field created by the magnets, in order to permit high-speed operation. Since the SESM has complete control of the rotor current, and thus rotor flux, it can reduce the flux levels as required during high-speed operation. Which, by-the-way, is an operating point where the average EV spends the majority of the time.

These alternate machine designs are further indications that the xEV industry is still evolving at fundamental levels and innovation will still be creating many future design opportunities for the semiconductor industry. We are developing several Exciter Module solutions to be used for the control of the SESM field coil current.