The Electric Vehicle (EV) revolution is here to stay. False starts have popped up during the history of transportation, but this time there is no stopping it. How this revolution will affect automotive transportation is a developing story. With advances in technology and power generation, many vehicles will have an option or standard offering for an electric powertrain in the near future.

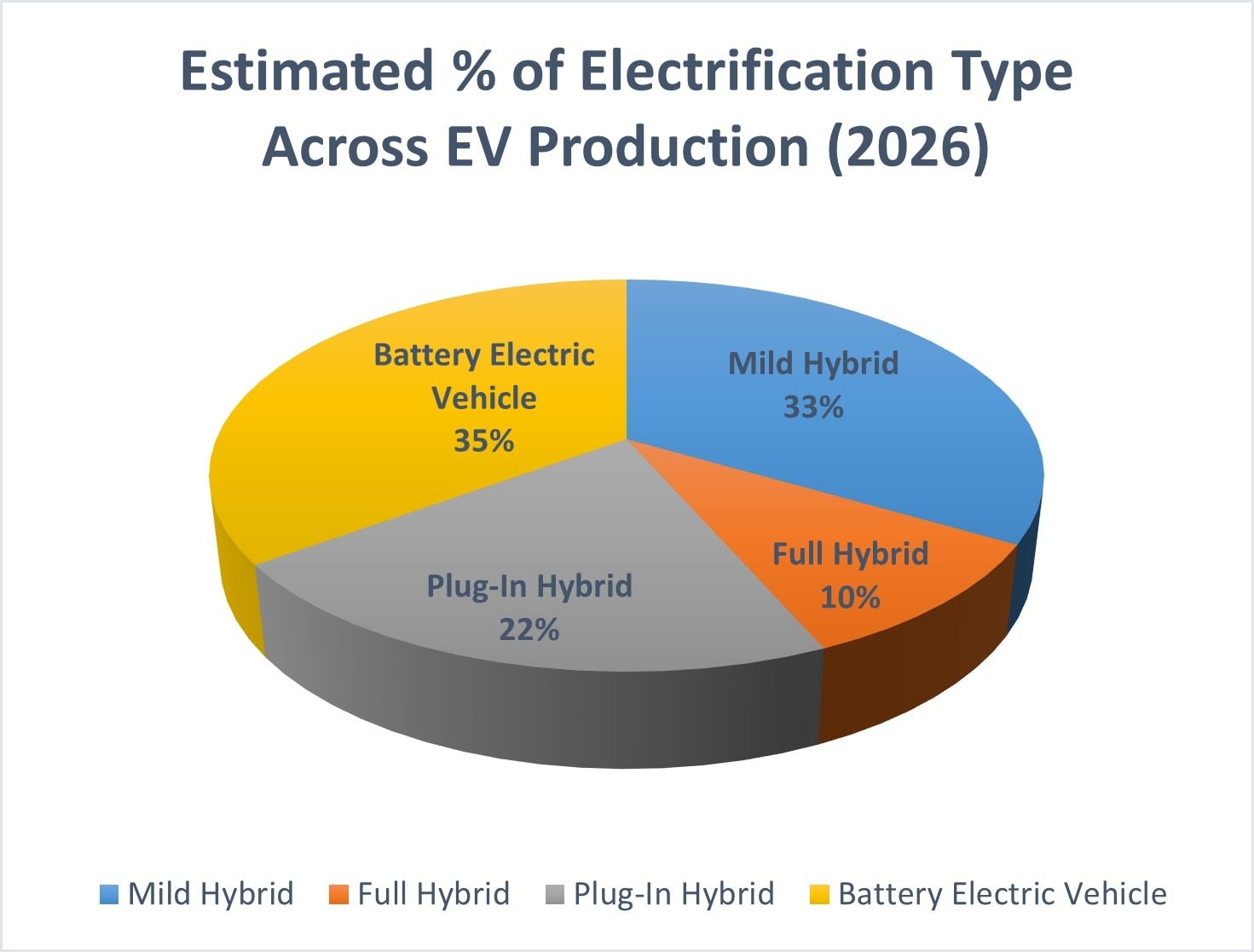

Every day you hear about a new EV added to a manufacturer’s lineup, the goal for being carbon neutral or electrification strategy. In this blog, we will focus strictly on Battery Electric Vehicles (BEV), also known as Zero-Emission Vehicles (ZEV). BEVs will make up approximately 35% of all EVs produced in 2026 accounting for over 13 million units.

A BEV replaces the internal combustion engine (ICE) with an electric powertrain, replaces fossil fuels with a large lithium-ion battery and refuels by charging the battery pack from the electrical distribution grid. An upcoming blog in this series will discuss the differences between classifications of EVs.

Figure 1. Electrification Classification for EVs in 2026 (FCEV = 1%, not shown)

For consumers, there are many use cases where it makes sense to shift from a traditional ICE vehicle to a BEV. The average daily work commute in the U.S. was less than 30 miles (48 km) roundtrip before the global pandemic of 2020. Considering the typical range of a BEV, it is clear that they can handle the daily commute without re-charging. Not only the commute but also other daily tasks such as picking up your children from school, going grocery shopping, heading to the gym and running other errands, are all possible before needing to re-charge. The traditional ICE vehicle can also handle these tasks, but in doing so, it releases an average of 12 kg (27 lbs) of CO2 for the same roundtrip work commute.

According to the Environmental Protection Agency (EPA), the average passenger vehicle releases 4.7 metric tons of CO2 into the environment in a year. When considering the number of vehicles on the road worldwide, that equals over 6.6 billion metric tons of CO2 released into the environment every year. Countries are enacting limits to help reduce CO2 output from the transportation sector, making the electrification of the powertrain a prime focus for all vehicle original equipment manufacturers (OEMs). For perspective, the annual CO2 output from vehicles is equivalent to the annual CO2 output of 564 coal-fired power plants, based on estimates from the United States Geological Survey (USGS).

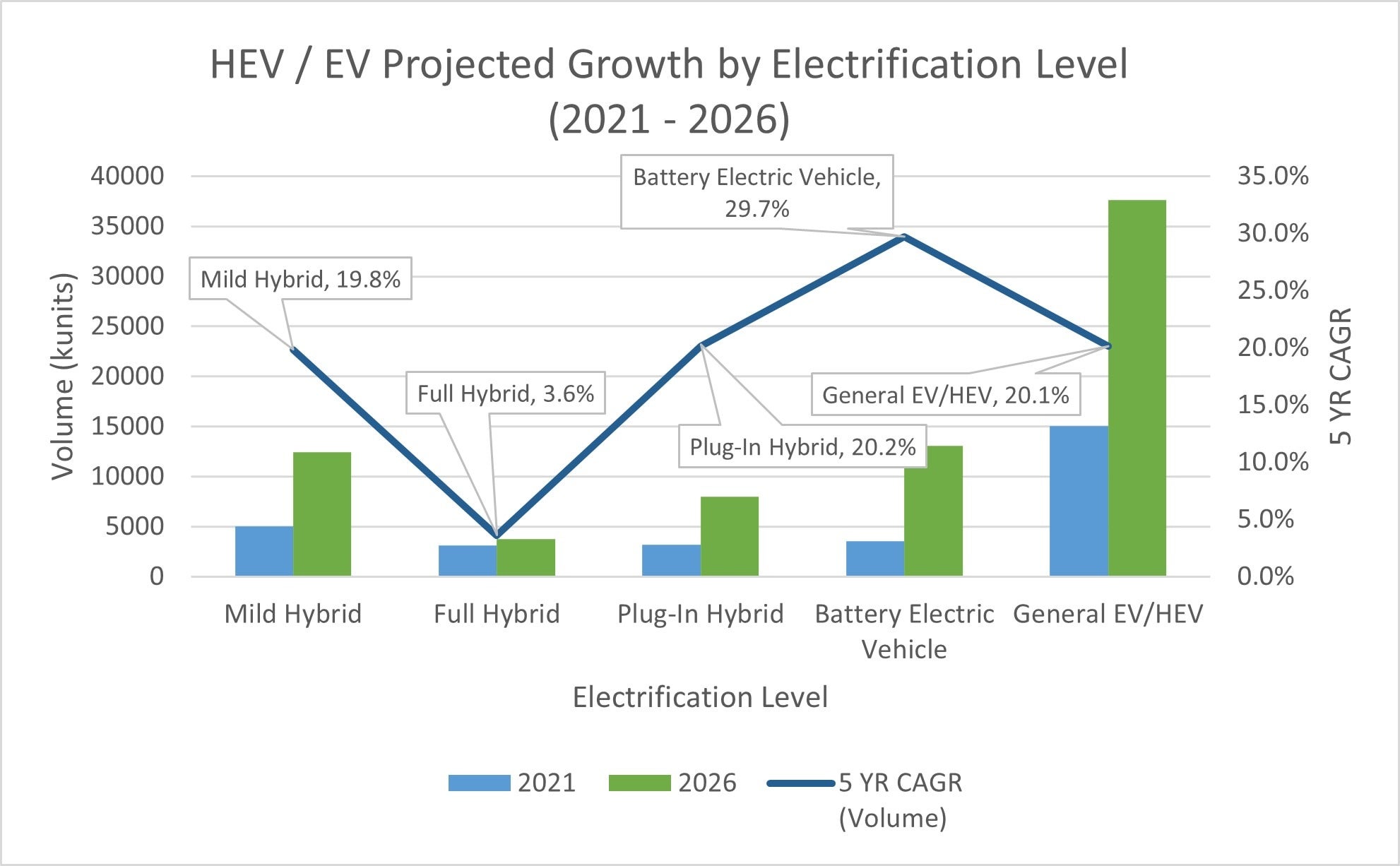

There are many challenges to overcome for the broad adoption of BEVs. Improvements in electronics efficiency, charging time, battery chemistry, residential and commercial infrastructure and lithium resource extraction will help solve those challenges. As technology advances and addresses these issues, the adoption of BEVs will increase. There will no longer be an associated performance gap as compared to an ICE vehicle. Advancements in range, charging time, environmental impact, cost of ownership and consumer satisfaction will drive us towards an electric future. In many instances, these advancements are already happening. Consumer opinions along with more stringent global CO2 emission requirements are accelerating this movement. This momentum means the expected EV/HEV compound annual growth rate (CAGR(VOL)) will be 20.1% from 2021 to 2026 and BEVs will have a CAGR(VOL) = 29.7%.

Figure 2. EV / HEV Growth for the Next 5 Years

Several electronic modules make BEVs possible such as the traction inverter, onboard charger (OBC), high-voltage/low-voltage DCDC and battery management system (BMS). These electronics allow the conversion of stored energy to power the traction motor, charging of the battery pack and power management within the vehicle.

ON Semiconductor offers cutting-edge automotive-qualified solutions to drive this electric powertrain revolution. The portfolio includes Silicon Carbide (SiC) MOSFETs, SiC diodes, hybrid IGBTs, Super-Junction MOSFETs and Automotive Power Modules (APM), allowing customers to design high-end systems that address an array of power tiers while maximizing power density, efficiency and reliability.

Learn more about our vehicle electrification solutions:

• Wide Bandgap Offers Faster Charging Capabilities for Electric Vehicles

• The Future of Electric Vehicles (video)

• Silicon Carbide (SiC) Solutions for Electric Vehicles (video)

Be sure to subscribe to our blog and follow us on social media to receive the latest updates on our technologies, solutions and company news!

Twitter | Facebook | LinkedIn | Instagram | YouTube