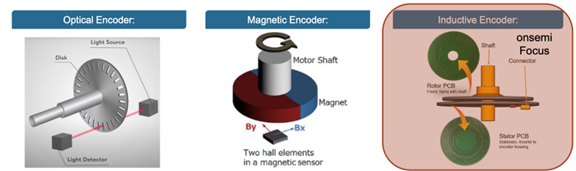

The world we live in is becoming more automated, bringing greater convenience as well as saving time and cost. Many applications, especially those in the industrial and automotive sectors, require motors to deliver this automation. In turn, this requires accurate control of the motor – primarily, knowing the position and speed of the rotor, typically attached to the shaft. The three most common technologies for this are optical, magnetic, and inductive.

Optical encoders offer good accuracy and are insensitive to the magnetic fields found in many applications. However, it is expensive and easily affected if dirt contaminates the rotating disc, light source, or light detector.

Magnetic encoders offer a low-cost solution and are often used in high-volume applications where accuracy is not the primary concern. While they are insensitive to dirt, they can be negatively impacted by magnetic fields that are often present in industrial or automotive applications.

Inductive encoder offers higher position accuracy than magnetic solutions, lower cost vs. optical encoders, and are ideal for rugged environments as they can cope with high levels of contamination, vibration and external magnetic fields. Additionally, inductive encoders are not temperature sensitive, and they have a low component count that reduces size, cost and complexity. From an environmental perspective, the non-reliance on rare earth materials (used in some magnets) is a further benefit.

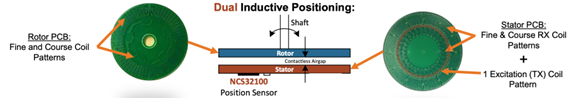

NCS32100 Dual Inductive Position Sensor

onsemi’s NCS32100 Dual inductive position sensor enables world-class contactless position accuracy better than + 50 arcsec, or 0.0138 degrees mechanical rotation using two simple, yet innovative, PCB discs. One PCB is attached to the motor’s stator (stationary), while the other single-layer PCB is fixed to the rotor or shaft. Both PCBs are parallel to each other, separated by a 0.1mm to 0.5mm air gap. The NCS32100 is located on the stator PCB.

The fine and coarse (Dual) conductive traces or coils are printed on both disc surfaces. A third conductive trace called the excitation coil is printed on the stator PCB. The NCS32100 transmits a 4MHz sine wave into the excitation coil, creating an electromagnetic field around the stator excitation coil. Due to Faraday’s law of mutual induction, the rotor’s fine and course coils intersect with the electromagnetic field, coupling energy onto the rotor coils, in the form of eddy currents.

Meanwhile, the stator’s fine and course coils connect to up to eight NCS32100 receiver inputs. When the rotor spins, the rotor’s eddy currents disturb the stator receiver coils. The NCS32100 measures the rotor position by processing these disturbances with proprietary algorithms inside its internal digital signal processor (DSP).

The NCS32100 achieves ± 50 arcsec position accuracy at rotational speeds up to 6,000 revolutions per minute (RPM), and is capable of providing positions at speeds up to 45,000 RPM – albeit with slightly reduced accuracy.

This simple solution requires few electronic components to be deployed, ensuring small size and low cost. It also remains completely insensitive to temperature fluctuations, contamination, and external magnetic fields.

onsemi’s NCS32100is a high-accuracy rotary position sensor that was developed to reduce breakdowns, stretch maintenance schedules, maximize throughput, and minimize maintenance costs for industrial applications.

The device contains an oscillator to provide the 4MHz excitation signal and demodulates the returned waveforms before converting them to the digital domain and processing them. This information is fed into an Arm® Cortex® M0+ microcontroller (MCU), that gives the solution high levels of configurability.

Capable of providing rotational velocity information at speeds up to 45,000 RPM, the NCS32100 is an absolute encoder, meaning that it can deduce position without any rotation of the discs. At speeds below 6,000 RPM the NCS32100 provides ±50 arcsec accuracy – a performance only achieved with optical encoders – until now.

Calibration of the sensor can be completed in mission mode using an internal routine in under two seconds, via a single command - provided that the rotor is moving at between 100 and 1000 RPM. The resulting coefficients are stored in non-volatile RAM (NVM) for reference.

Despite its performance, the dual inductive approach retains the simplicity of other inductive position solutions. For comparison, the creation of an optical solution involves an optical disc, stator PCB and LED driver – totaling 100 components.

By contrast, an NCS32100-based solution only requires a pair of PCBs, with a total of just twelve components. This solution delivers the same accuracy as the optical solution.

Automotive Applications

In automotive applications, while cost and reliability are important, safety is paramount - especially in applications such as steering or braking. onsemi’s NCV77320 absolute position sensor for automotive use is designed following ISO26262 specifically for these critical use cases. The NCV77320 position accuracy is 1,943 arcsec, or 0.539 degrees mechanical rotation mainly because it has only 3 receiver inputs vs. the NCS32100 with 8 receiver inputs, and the NCV77320 does no support fine and course coil PCB configurations. However, the NCV77320 can operate as a rotary encoder or a linear encoder.

NCV77320 applications include brake pedal sensors, accelerator pedal sensors, motor position sensors, brake system sensors, vehicle level sensors, transmission range sensor, throttle position sensor, and exhaust gas recirculatory sensors.

Like the NCS32100, the NCV77320 is insensitive to contamination, changes in temperature and magnetic interference and the device can be used in automotive environments with an ambient temperature in the range of -40ºC to +150ºC

onsemi’s NCS32100 and NCV77320 inductive position sensors are a superior solution to optical and magnetic encoders for industrial and automotive applications. To learn more about onsemi’s inductive position sensors, watch our webinar” Inductive Position Sensors for Industrial and Transportation Markets”.