No matter how good your strategy, it never seems to add up to much without the proper execution. Jokes about the early years of the Tampa Bay Buccaneers or Groucho Marx aside, successfully following through on plans is vital, whether in sports, business, construction, or any other area.

Image sensor development is no exception, as even the best ideas need to be implemented into a product. Step by step, each component of a product family’s strategy needs to be developed and implemented, allowing the products and features available to the market to grow one by one.

That’s what ON Semiconductor has been doing with our Interline Transfer EMCCD technology, which enables cameras to image at video speeds under sub-lux illumination – down to the light coming only from stars on a moonless night. We’ve been building our portfolio of image sensors based on this technology step by step, starting with the award-winning 1080p resolution KAE-02150 and then adding different pixels and new resolutions and packaging options. And now, we’re taking the next step to drive more technology advancements through the portfolio.

Today, we’re announcing the new KAE-08152 image sensor, which builds on the existing 8 megapixel KAE-08151 by incorporating the enhanced NIR pixel design already available in devices such as the KAI-02152. This change doubles the quantum efficiency of the device for wavelengths such as 850 nm, which can be critical in applications such as microscopy and scientific imaging, as well as commercial and military applications for high-end surveillance. And since no electrical changes are needed and the parts share the same package and pin-out definitions, the KAE-08152 is fully drop-in compatible with the existing KAE-08151.

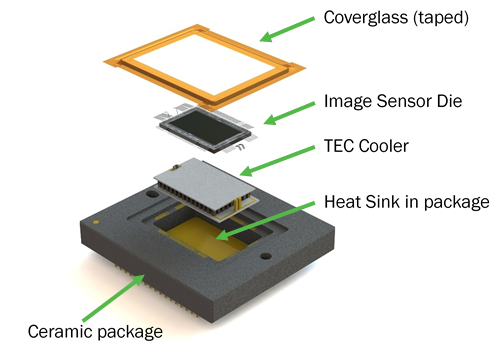

In addition, we are expanding availability of packages that incorporate an integrated thermoelectric cooler throughout our full IT-EMCCD portfolio, with all five devices now available in an optional cooled configuration. With the extreme sensitivity available from this technology, cooling is important to reduce spurious background signals – and integrating a cooler directly into the product’s package simplifies with work needed by camera manufacturers to develop a cooled camera design.

With these changes, there are now almost 30 production configurations available in our IT-EMCCD portfolio, with options for different resolutions and pixel sizes; color, monochrome, and Sparse CFA sensitivity; standard and enhanced NIR sensitivity; integrated cooling, and more. And we’re not done, because there are still more products and ideas we are actively working on to expand this portfolio. All we need now is to keep executing.

Step by step.