Motors are responsible for consuming more than 50% of the produced power in industrialized nations. At least 80% of these motors are AC induction motors (ACIMs) and devour energy at an average efficiency of only 44%. Ever-increasing electricity costs are slowly driving legislation and guidelines which dictate efficiency improvements for motors used in residential and industrial applications. These improvements in efficiency come primarily from two paths:

1) Using intelligent electronic controls to more effectively drive induction motors

2) Transitioning from ACIMs to permanent magnet-based brushless DC (BLDC) motors.

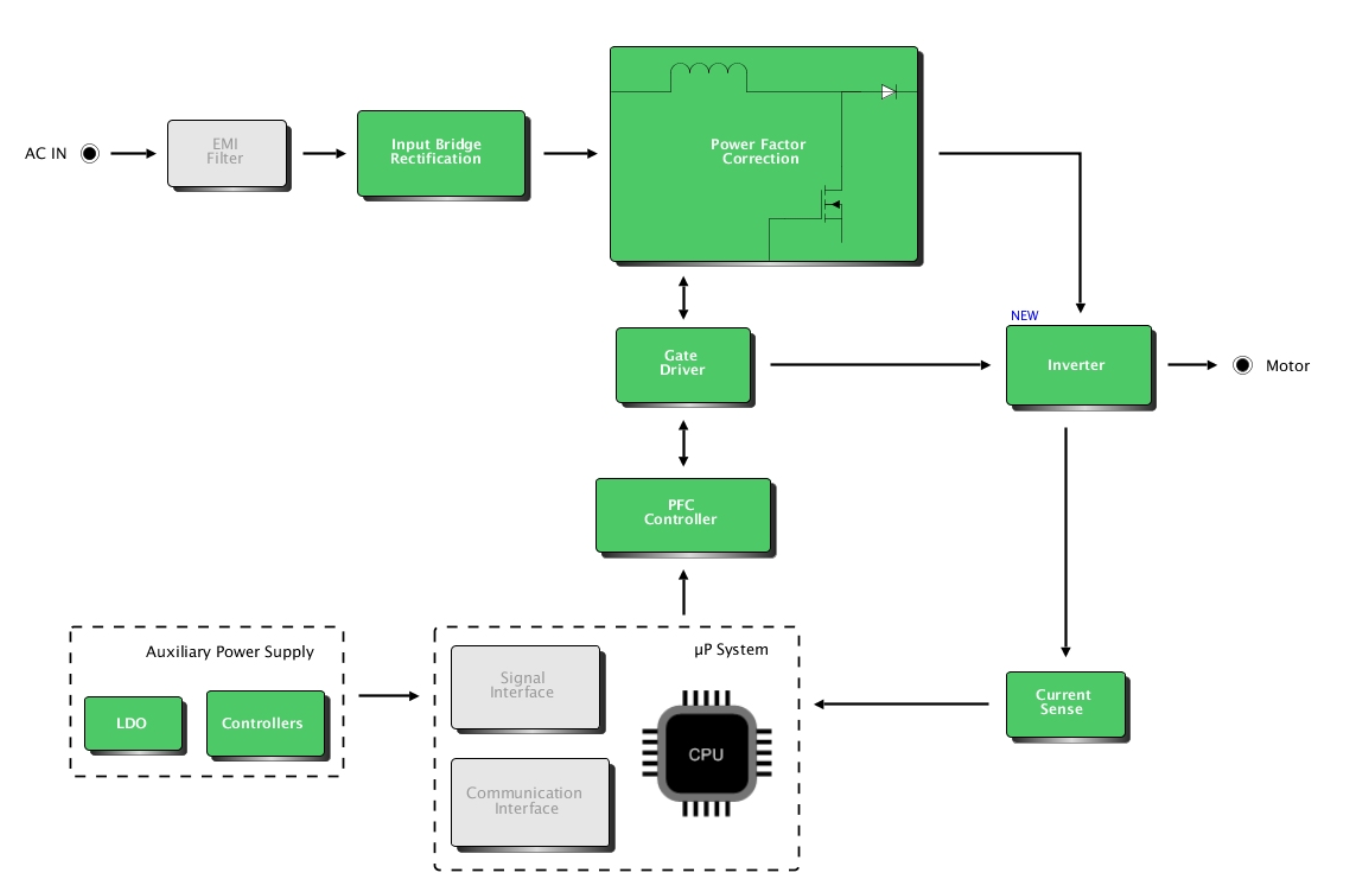

Both paths require power semiconductor-based inverters. At its core, a 3-phase motor inverter sourced from the AC line is comprised of the following circuit blocks:

The term Industrial Motor Control encompasses a wide array of end applications, environments, and ultimately specifications. This block diagram represents the largest segment of mid-power motor controls which are powered from the AC line, with attached motors ranging from zero to 7.5 horsepower (hp). At these power levels, AC input voltages of 120 to 460 VAC are common, depending on the installation location. Some locations will have single-phase power, while others will offer 3-phase connections. To meet these diverse application conditions, a motor control designer must have access to an equally diverse selection of power semiconductors and associated support. At ON Semiconductor, we have an extensive portfolio with hundreds-to-thousands of viable solutions across the various blocks, depending on the target specifications. This includes our motor-specific power silicon product lines, which are known throughout the industry for their performance, reliability, flexibility, and cost-effective design.

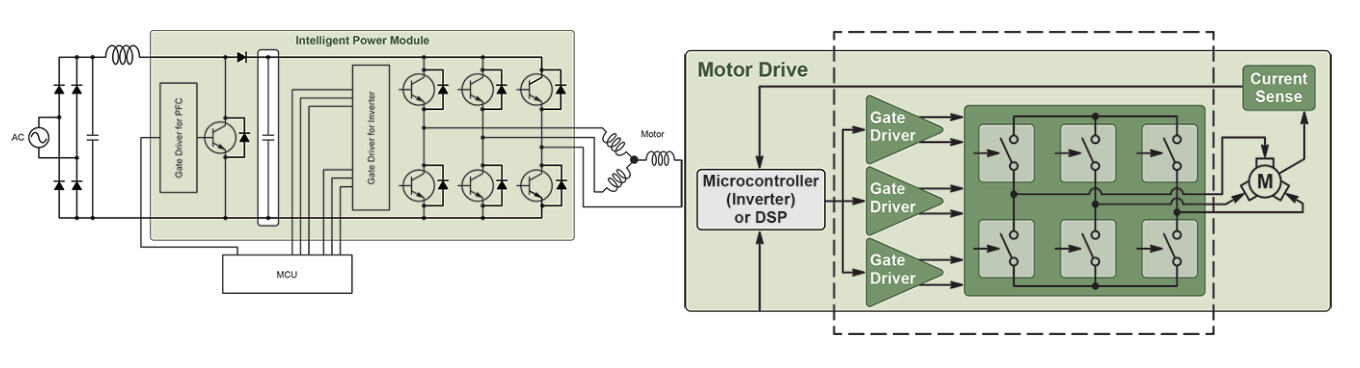

In addition to our extensive offerings, ON Semiconductor offers full system solutions for both paths with a 3-phase motor inverter sourced from the AC line at its source. The Intelligent Power Modules (IPMs) offer 3-phase inverters integrated with drive circuitry in thermally optimized packages ranging from power ratings of 50W – 10kW. IPMs are highly-integrated semiconductor modules equivalent to the above power semis plus many passive discretes.

By any account, a typical IPM replaces between 45 and 100 discrete components. They are designed to be fault tolerant, PCB friendly, heat sink compatible, and easy to interface with a controller IC. Additionally, they have built-in isolation of >=2kV from their thermal interface to the heat sink. These high-density modules make them an ideal low-EMI solution that meets the rigors of safety agency compliance. IPMs are the go-to solution for industrial motor controls below 10 hp. Power Integrated Modules (PIMs), take the stage from 10 hp to >100 hp. It is important to not confuse the 3-phase motor output with the number of phases of AC line input power. These are unrelated. Most industrial motors being driven by inverter motor controls are manufactured with their windings in a three-phase arrangement. Our IPMs are specifically designed to drive 3-phase motors of various types: AC induction motors (ACIMs), brushless DC motors (BLDCs), brushless AC motors (BLACs), and permanent magnet synchronous motors (PMSMs) to name the most popular. In addition to power semi solutions for 3-phase motors (ACIM, BLDC, BLAC, PMSM, etc.), we also have complete solutions for permanent magnet DC (PMDC) motors and stepper motors.

Current and voltage sensing are at the heart of every industrial motor control. In order to ensure each of motor windings are supplied with current at the proper interval, the high precision, zero-drift operation amplifiers portfolio offers cost effective and reliable products to monitor and report phase currents to the microcontroller which will determine the next inverter leg to fire.

Explore our interactive block diagram and build a customized product list to complete your design.