As power demands rise across countless industries, including automotive, industrial, and AI data centers, engineers face the dual pressures of delivering enhanced performance while meeting stricter environmental standards and efficiency expectations. In addition, for smaller, low-power devices like medical wearables, the market demands are moving quickly, requiring additional intelligence and functionality to improve personal care, while efficiency and device costs remain crucial.

These evolving needs call for highly integrated power and sensing solutions that provide greater intelligence and energy efficiency, meeting the diverse demands of applications across the power spectrum.

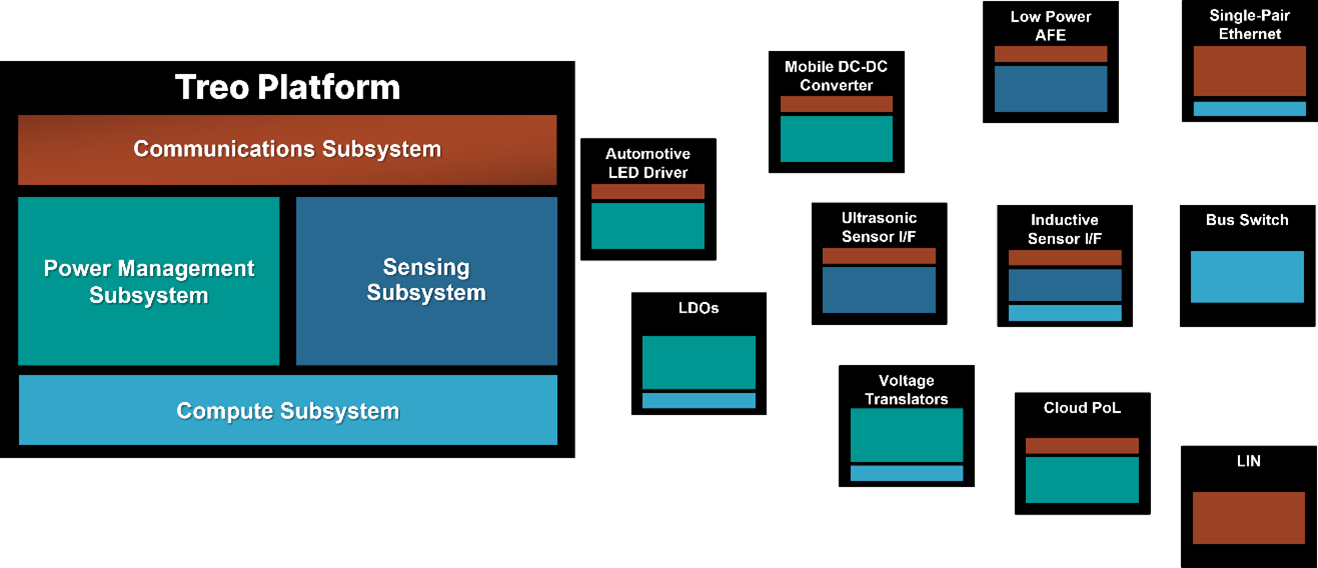

Supporting these critical requirements is no simple task, so onsemi has engineered a new analog and mixed signal platform, Treo, specifically designed to deliver much-needed efficiency, integration, and performance. With the use of Bipolar-CMOS-DMOS (BCD) process technology on a 65nm node, and the ability to support a voltage range of 1 - 90V, the Treo Platform will expand onsemi’s range of intelligent power and sensing technologies to deliver the next-generation of power management ICs, sensor interfaces, purpose-built communication devices and reliable standard products.

What is the Treo Platform?

The Treo Platform is constructed of an ever-evolving set of reusable analog, digital and power IP building blocks that will deliver the next generation of power management ICs, sensor interfaces, communication devices, standard products and more.

In many applications within automotive, industrial, medical and AI data centers, competitive advantage starts with the performance and advanced features semiconductors enable in the end-product’s design. With this being key to the success of so many businesses, the market is demanding ever more performance, more sophisticated feature sets and tighter integration. The Treo Platform integrates this within the next-generation of onsemi analog and mixed-signal product portfolios.

Already multiple products have been developed from the platform and are sampling now, including voltage translators, LDOs, and multi-phase controllers. Some have been developed for the mass market, while others are customer-specific.

Starting in 2025, onsemi will use the platform to deliver an even broader array of products including inductive position sensors, 10BASE-T1S Ethernet controllers, DC-DC converters, multi-phase controllers, automotive LED drivers, electrical safety ICs, gate drivers, and more.

Products developed on the Treo Platform will be manufactured in onsemi’s world-class 300mm fabrication facility located in the USA in East Fishkill, NY. The state-of-the-art plant is capable of manufacturing 65 nm technologies, as well as being automotive-qualified and ITAR-certified.

Why the name ‘Treo’?

Well, with ‘Treo’ being centered around ‘three’, it should come as no surprise that there are three main reasons for naming the platform ‘Treo’ (pronounced Tray-o).

- “Tre” means ‘three’ in Spanish and Italian, which reflects the core of the 65 nm BCD platform - integrating Bipolar, CMOS and DMOS to bring together analog, digital and power solutions.

- It also represents “Tree” – a nod towards the broad analog and mixed-signal product portfolio that will be the many technology “branches” of the platform

- In Spanish, “Treo” is a certain type of sail in sailboats – vessels with similar agility and high performance as the platform itself

BCD Technology

The Treo Platform is based upon BCD technology that integrates the best of three types of transistors on a single chip:

- Bipolar transistor for Analog functions

- CMOS (Complementary Metal-Oxide Semiconductor) transistors for digital processing

- DMOS (Double-diffused Metal-Oxide Semiconductor) transistors for power and high-voltage elements

While other BCD platforms exist, the onsemi Treo Platform is unique in that it offers a wider voltage range (1-90 V) than any other platform currently available. The advanced 65 nm process technology enables an unprecedented level of integration alongside reduced power consumption.

The platform is designed to offer a reliable and consistent foundation for various applications by using pre-developed analog, digital and power design modules or IP blocks. These IP blocks can be combined in endless configurations to develop new Treo products and help to simplify the design process for onsemi’s engineers, allowing for faster product development while guaranteeing high integration and quality.

Benefits of the Treo Platform

With the huge flexibility inherent in the BCD technology upon which it is built, the Treo Platform enables a variety of power, sensing, and communications product portfolios to be delivered to customers rapidly.

Like a tree, the platform enables various “branches” of technology, each representing a distinct product family that leverages the benefits of the platform. The modular nature of the platform will increase the breadth of products customers can obtain from onsemi and enable them to meet emerging market requirements faster than ever before.

Inbuilt high accuracy analog capability allows the Treo Platform to deliver higher levels of performance in the end system. Examples include better obstacle detection in ADAS systems or more accurate measurements in continuous glucose monitors (CGM).

With its unmatched operating voltage range, Treo allows for more functionalities to be combined in a single package, thereby reducing the complexity and size of designs. Furthermore, the incorporation of advanced digital processing capabilities can enhance the level of integration and functionality provided by final products.

The Values-Driven by the Treo Platform

The Treo Platform integrates complex analog and digital signal processing along with MCUs and multiple other functions with common CMOS and backend, enabling IP to operate across low, medium and high voltage levels. The high-performance analog functionality built into the platform offers better speed and improved matching performance than traditional analog approaches.

Drawing inspiration from its namesake sail, the Treo Platform is engineered for performance and agility. This philosophy is evident in its exceptional thermal capabilities, boasting a proven operating temperature limit of 175°C, with certain models capable of withstanding up to 200°C. This surpasses competing solutions by a significant margin of at least 25°C, enabling greater heat dissipation directly on the chip, which in turn can lead to a reduction in the bill of materials (BOM) cost.

Conclusion

The Treo Platform will allow for rapid development of future analog and mixed-signal chips. The first product families developed on the Treo Platform are available for sampling today, which include voltage translators, ultra-low-power AFEs, LDOs, ultrasonic sensors, multi-phase controllers, and single-pair Ethernet controllers. Through 2025, onsemi is set to expand its range of innovative Treo product families, adding new high-performance sensors, DC-DC converters, automotive LED drivers, electrical safety ICs, connectivity, and more.

For more information about the Treo Platform, visit onsemi.com/treo or request samples.