Vehicles have been powered by internal combustion engines (ICE) for over a century. However, you cannot fail to notice that things are changing rapidly with the rollout of electric vehicles (EV). This topic is being discussed across the automotive industry and in mainstream news outlets.

When we think of an EV, many people think of pure battery electric vehicles (BEV). However, the EV segment consists of MHEV (mild hybrid), HEV (hybrid), PHEV (plug-in hybrid) and BEV variants. The MHEV architecture provides a low impact path for automotive manufacturers to modify an existing vehicle platform and reduce CO2 emissions, while still being able to cover long distances regardless of the availability of charging stations.

The belt starter generator (BSG) or integrated starter generator (ISG) is part of this rapid EV development, specifically for MHEVs. This unit effectively combines the functionality of the starter motor and alternator in an ICE vehicle and allows for the creation of the MHEV.

MHEVs typically have two batteries; the ‘traditional’ 12V lead-acid battery and a 48V lithium-ion (Li-Ion) battery. The 12V battery powers many of the ‘legacy’ systems while the 48V battery powers higher loads, such as the BSG/ISG to start the vehicle or provide electric boost/drive.

Implementing a BSG/ISG on an ICE vehicle enables a significant amount of extra functionality including start-stop, energy recovery during coasting/braking, energy generation from the ICE, and even electric drive (or boost) depending upon the vehicle. Some of these can be so subtle that the driver does not notice that their MHEV is different to a traditional ICE vehicle, except when the ICE shuts down during usage.

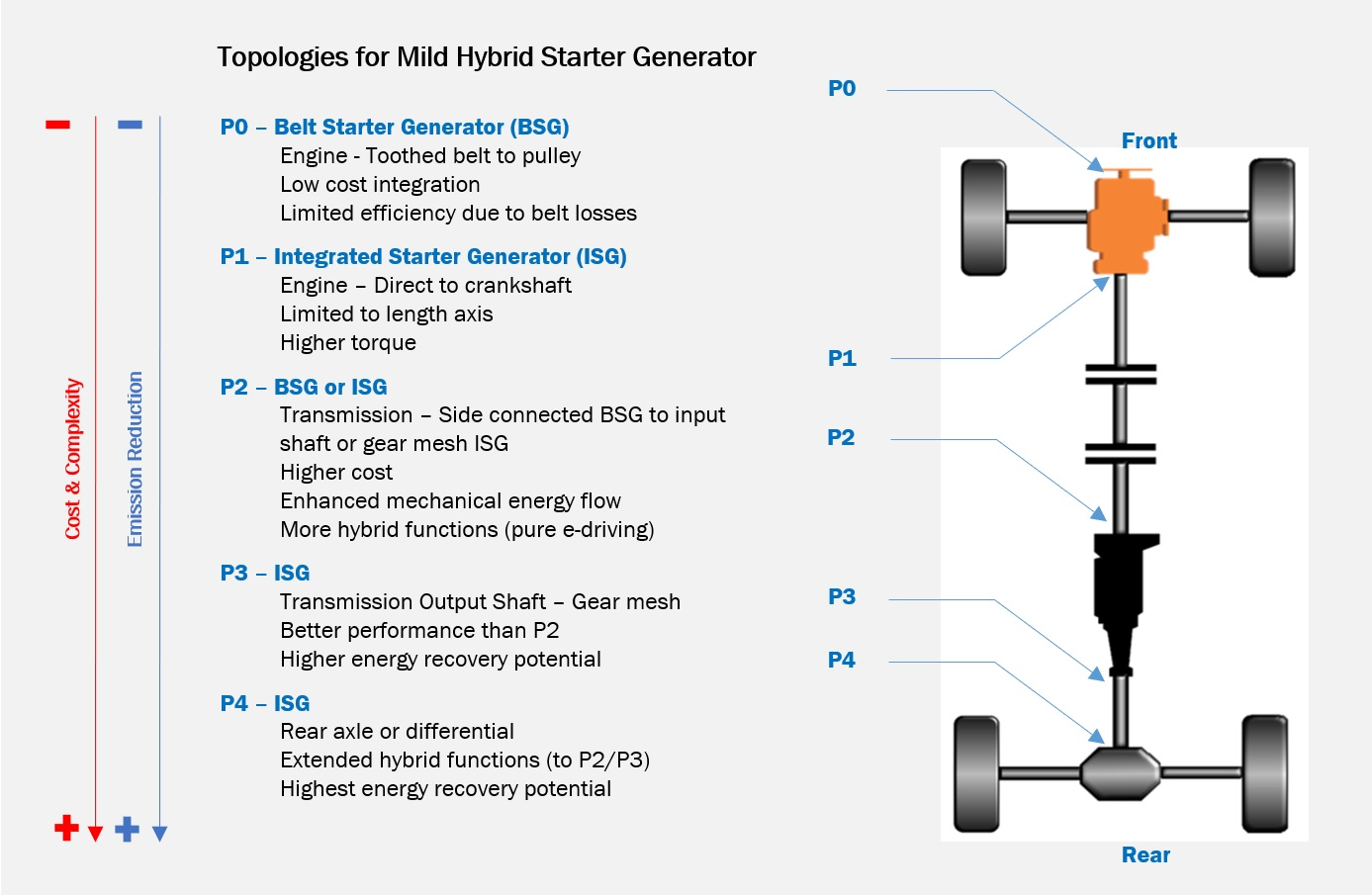

The functionality and performance are determined by where in the powertrain the BSG/ISG is positioned, as shown in Figure 1. The positioning also determines whether the device is a BSG (P0 or possibly P2) or an ISG (P1, possibly P2, P3 & P4).

Figure 1. Topologies for mild hybrid starter generator

While a MHEV is not a zero emission vehicle (ZEV) like a BEV, it does allow for a reduction in CO2 output as compared to ICE vehicles. This is especially evident in the slow-moving traffic of large cities where air pollution is generally at its worst – and where the effect on human health is greatest.

If mounted at P0 or P1, functionality is limited to start-stop and energy recovery. While P0 and P1 locations are easier places to integrate the unit, the benefit on emissions is the lowest here, as there is no energy recovery if the ICE is not rotating. In this arrangement the ICE shutdown algorithm is less aggressive, which reduces CO2 savings.

When positioned further back in the drivetrain (P2-P4), energy recovery is possible during coasting or braking when the ISG is functioning as a generator. The motion of the vehicle will turn the rear axle or driveshaft, even if the ICE is off. As the ISG is now independent of the ICE, more aggressive shutdown algorithms are possible which allows for greater CO2 reduction. Additionally, in these positions, electric drive is possible meaning that the vehicle can be moved by the ISG while functioning as a motor. This can be useful in start-stop traffic or for moving off from a standstill before engaging the ICE for higher speeds.

The power output from the BSG/ISG is typically in the range of five kW to 25 kW or more, although it is generally towards the lower end for belt-driven solutions due to the potential slippage of the belt when combined with high levels of torque.

Currently, MHEV represents one-third of all EVs sold. This proportion is expected to remain stable until at least 2026, while MHEV sales continue to grow at a CAGR of almost 20%.

High-performance BSG/ISG are critical to MHEV being able to attain their CO2 reduction goals. Constant power loads are high and there are frequent peaks of energy to contend with. Often the BSG/ISG is mounted where it has to endure elevated temperatures as well as dust and moisture from the environment. Given all of this, it is a challenge to design small, lightweight yet powerful units that are highly efficient and reliable in the long term.

ON Semiconductor has a wide range of advanced semiconductor technologies suitable for BSG/ISG designs. Their high power 80V and 100V MOSFETs are available as discrete components or integrated into automotive power modules (APM17M) that offer enhanced performance and simplified design. All components intended for automotive applications are AECQ-101 qualified, AQG-324 qualified (modules) and PPAP capable.

Learn more about our vehicle electrification solutions:

Be sure to subscribe to our blog and follow us on social media to receive the latest updates on our technologies, solutions and company news!

Twitter | Facebook | LinkedIn | Instagram | YouTube