Stringent emission laws, more comprehensive EV options, ease of access to DC fast charging (DCFC) infrastructure, and overall ownership cost reduction drive the Electric Vehicle (EV) market growth. Consumers’ change in mindset to support green initiatives further enables this growth.

Despite the pandemic, the EV market witnessed a growth of 41% in 2020, according to an International Energy Association (IEA) report. In comparison, the pure internal combustion engine (ICE) based cars showed a drop in sales of 16%. This growth momentum will continue. Market research consensus is that almost 50% of all consumer passenger vehicles will be electrified in the next five years.

With the EV market snowballing, new pure-play companies enter every year. Traditional automakers are working to transform their current ICE factories and pivot to the EV-based model to compete. Both carrot and stick are in action. The carrot is capturing this exponential demand and growing revenue substantially, and conversely, the stick is hefty fines for missing emission reduction deadlines.

Silicon Carbide (SiC) is at the Heart of Vehicle Electrification

Individual SiC components are more expensive than silicon devices. However, SiC-based solutions generally cost less at a system level due to SiC device efficiency and ability to operate at high voltage, high temperature, and high frequency. With its superior thermal efficiency, smaller passive components such as heat sinks can be used in tandem with SiC-based devices.

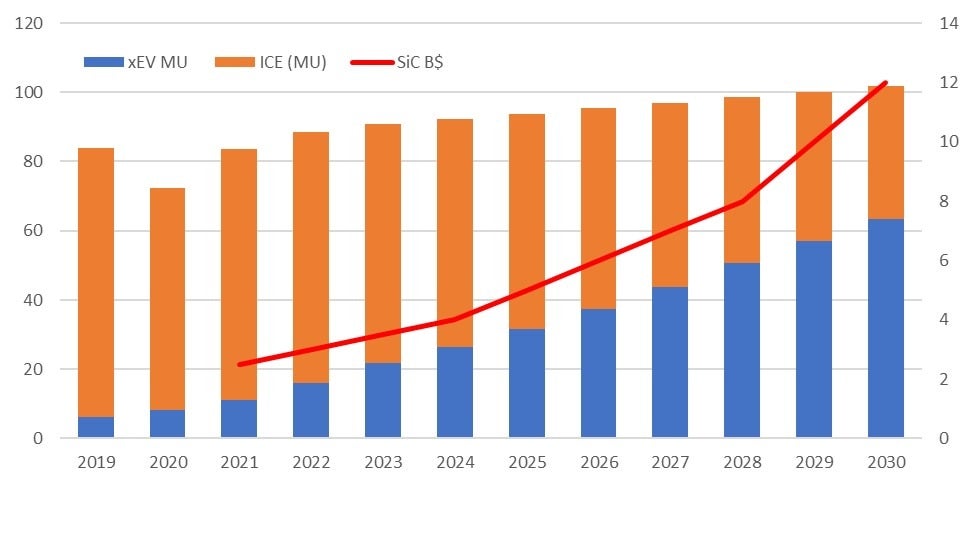

These distinct advantages of SiC have put it at the heart of vehicle electrification. Other industries also invest in SiC, including aerospace, defense, and energy infrastructure segments. Based on the market outlook, the SiC total addressable market is projected to grow from $2B in 2021 to $6.5B in 2026, at a compound annual growth rate of 33%, making it safe to assume the demand for SiC will outgrow the supply.

Recent years have shown how global macro events can substantially affect the entire chip supply chain—with SiC no exception. Shortages and lead time crises can adversely impact customers in various ways, including revenue loss and missing emission reduction goals in the case of government mandates. Mitigating supply risk is of the utmost importance, and carmakers cannot ignore the advantages of partnering with a vertically integrated SiC supplier.

How Can onsemi Solve This Problem?

For decades, onsemi has been a trusted partner of carmakers and original equipment manufacturers (OEMs) for intelligent power and sensing solutions. onsemi has put SiC as its core strategy to ensure our industry partners can fully harness the revenue growth from the EV market. onsemi is investing more than ever to expand its breadth and depth of SiC-based solutions, ecosystem support, and supply capability.

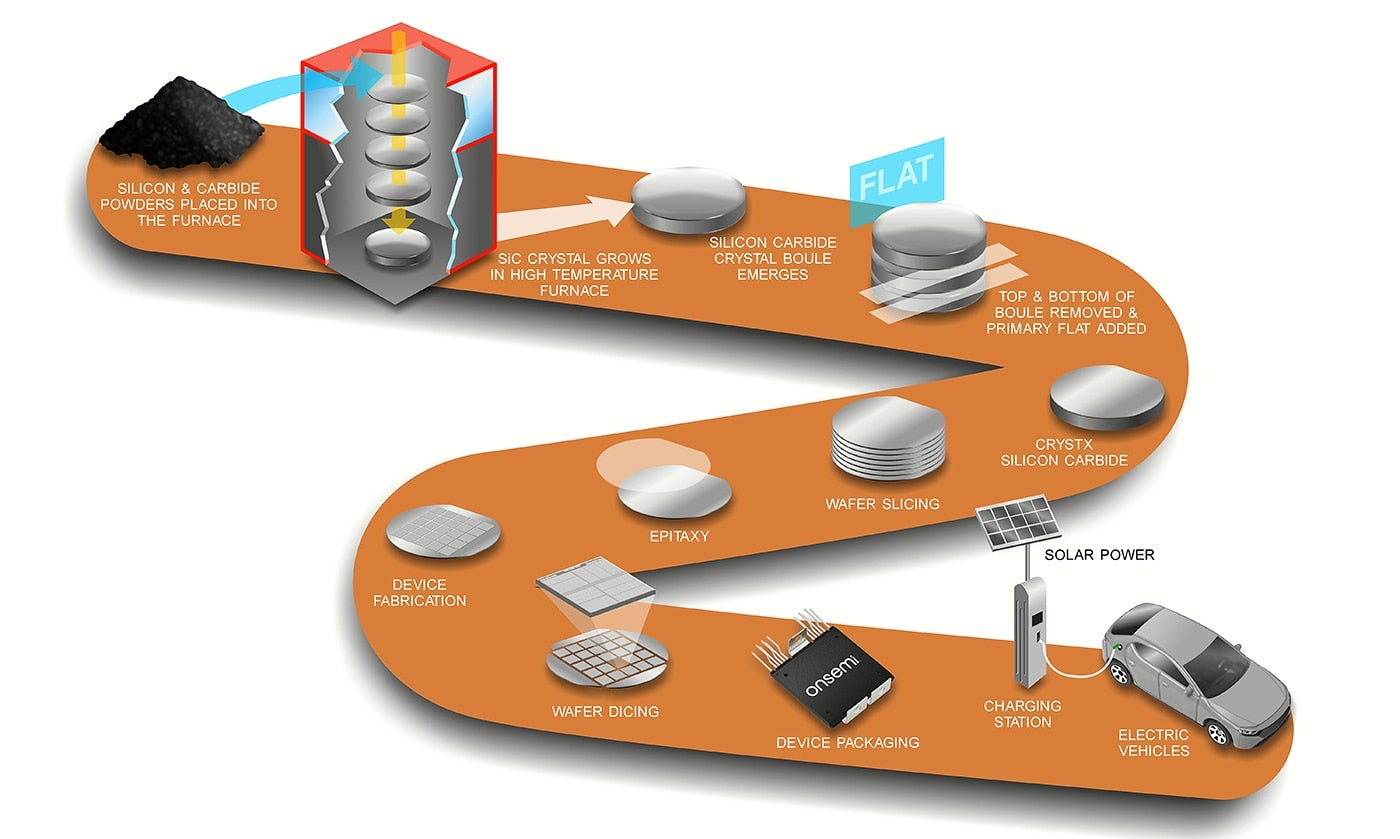

onsemi’s Fully Vertically Integrated Supply Chain – From Crystal to System

The supply chain begins by growing our single crystal silicon carbide material at our Hudson, New Hampshire facility. A thin epi layer is grown on the in-house substrate, which then goes through several device processing steps to packaging the final products. The whole manufacturing process is vertically integrated end-to-end, with complete reliability and quality testing to assure zero defect products.

A vertically integrated supply chain brings several advantages, such as ease of scaling, quality, and cost control. onsemi qualifies all products at 100% rated voltage and 175°C. The devices are also 100% avalanche rated, have intrinsic gate oxide reliability, and undergo cosmic radiation testing. Additional quality assurance comes from defect scanning performed before and after epitaxial growth. Vertical integration helps achieve a rapid scale-up of production footprint and process optimization due to quick feedback throughout the value chain.

onsemi offers a host of SiC solutions for vehicle electrification, giving customers the flexibility to choose discrete or module solutions based on their system requirements. Product offerings include a wide selection of SiC diodes, SiC MOSFETs, SiC modules, and silicon and SiC hybrid modules. onsemi provides technical support with world-class automotive and DCFC design experts, complete ecosystem design tools, and detailed technical documentation of physical, scalable SPICE Models to support customers at each stage of their design and development. (Try our SiC MOSFET SPICE Models and SiC Diode SPICE Models.)

In conclusion, SiC plays a critical role in charging the battery and driving the motors. Solutions based on SiC have more power, higher efficiency, and can drive further. With the increasing demand for SiC, choosing the right supplier and partner is essential. onsemi brings a unique value proposition with its breadth and depth of high-efficiency intelligent power solutions. With years of manufacturing expertise, verticalization with substantial capital investment, and expanded R&D efforts, onsemi enables its customers to achieve their goals.