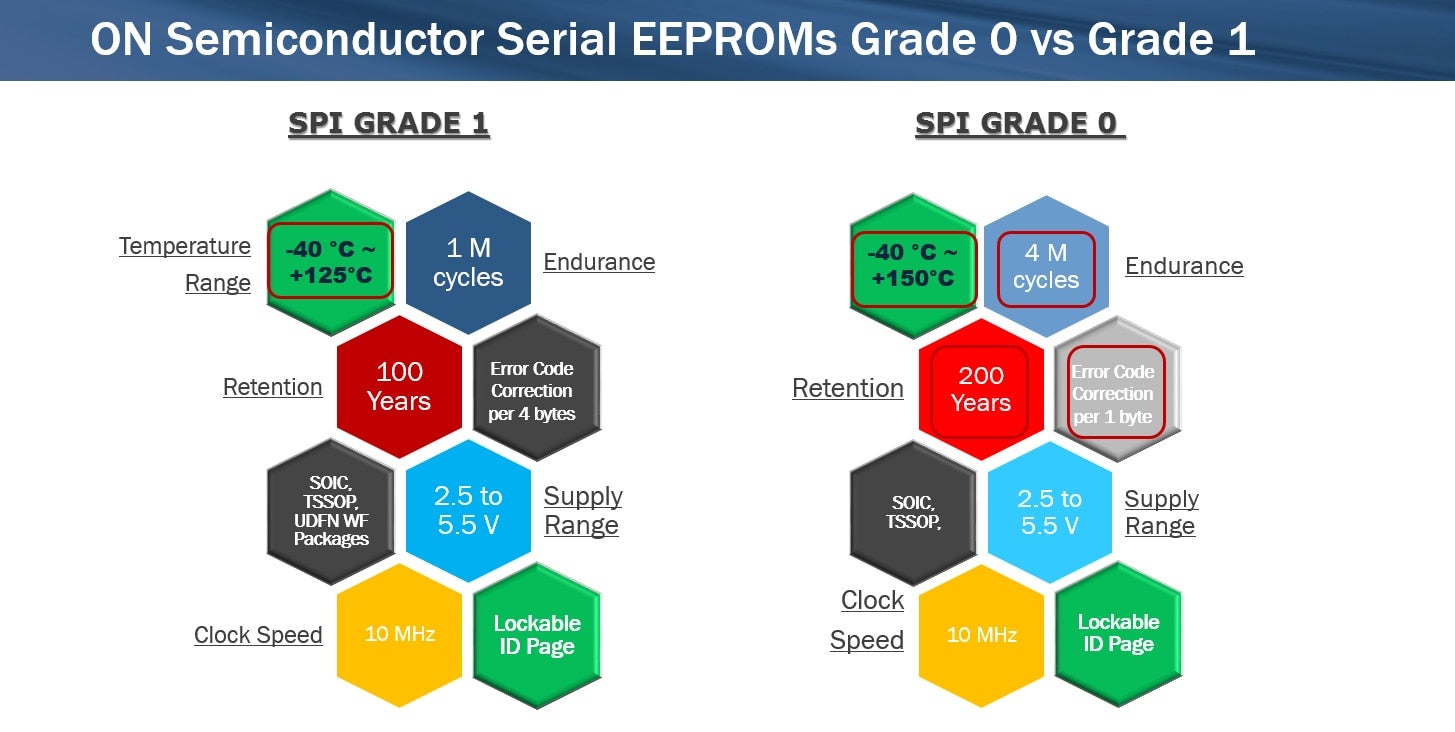

Harsh environments are all around us, but for integrated circuits they are even more numerous, the most common is probably the car. For the automotive industry, designing electronic control units for safety-critical features that can withstand temperatures of up to +125°C is commonplace. The industry standard for components that meet this requirement is AECQ-100 Grade 1, where Grade 1 shows that the component has been tested to operate in an ambient temperature of anywhere between -40°C and +125°C.

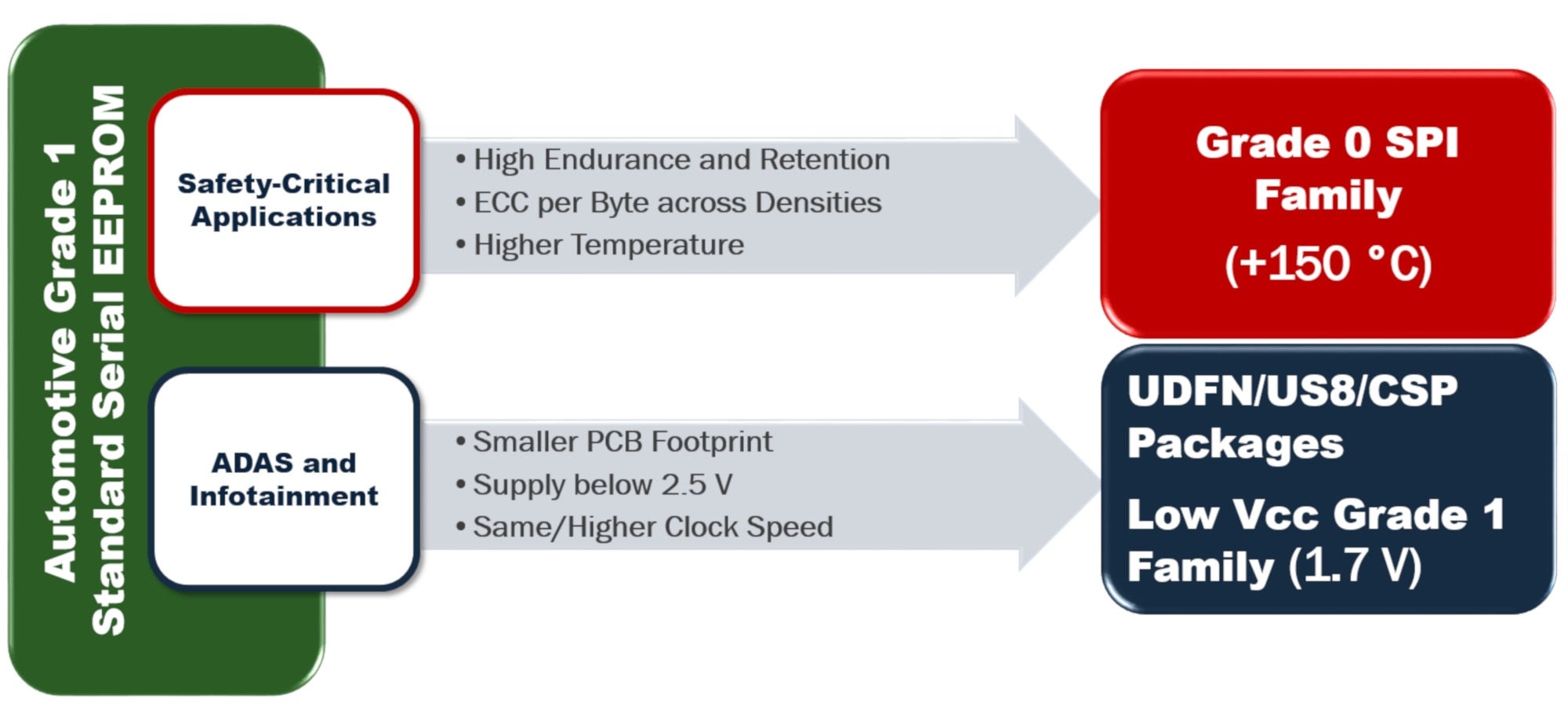

This is important because the data sheet for a component will typically specify performance at an ambient temperature of +25°C and show how this changes over temperature; the higher the operating temperature the better the performance over the entire temperature range. For this reason, manufacturers are keen to specify components that can now meet Grade 0, which is a temperature range of -40°C to +150°C, particularly for safety-critical applications such as driver assist, braking systems and general engine management.

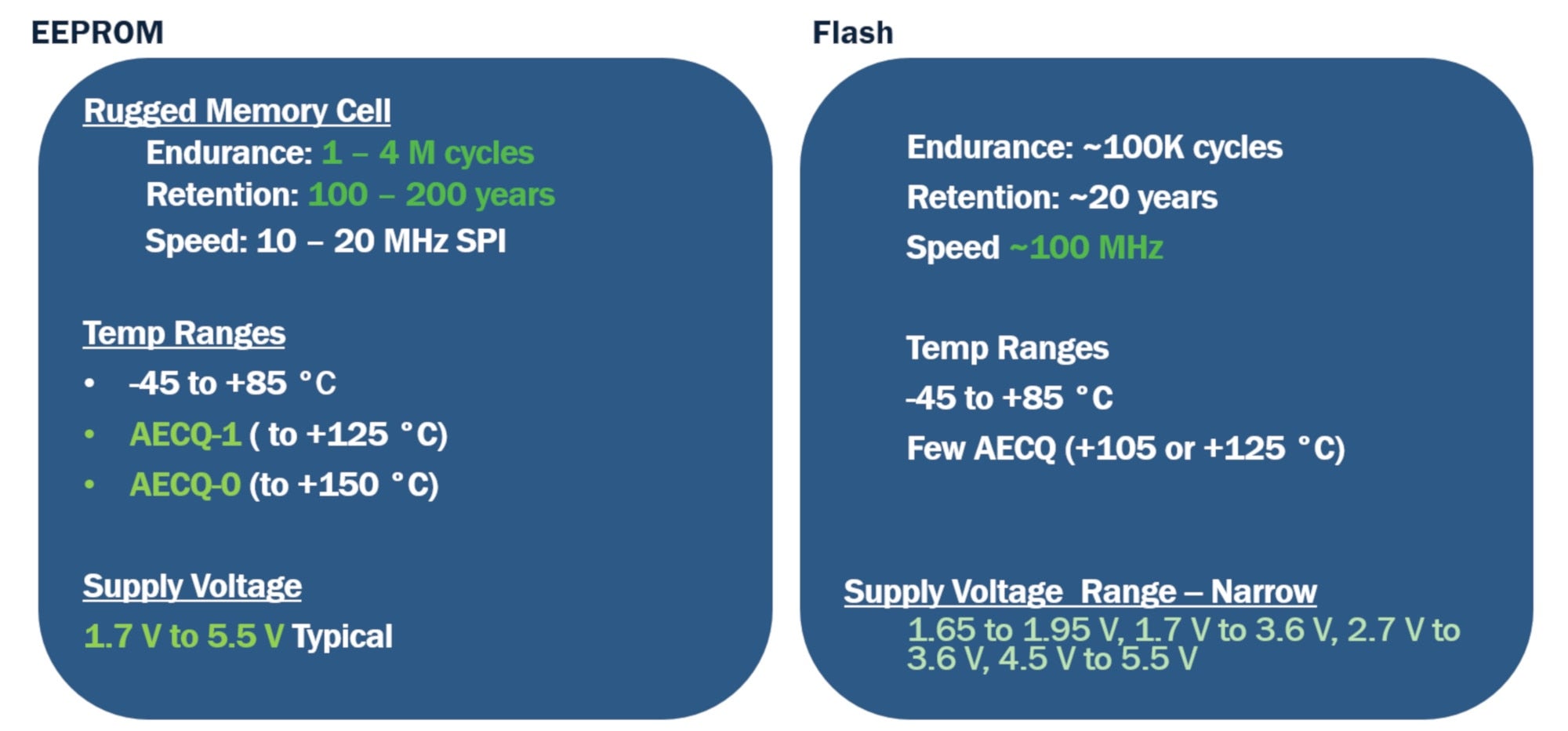

Many engine control units (ECU) now rely heavily on non-volatile memory to store calibration data, log data and firmware to enable these features. Flash memory is not well suited to Grade 1 or Grade 0 environments, because the underlying process has been optimised for consumer applications, which means high density and high performance. In an automotive application, speed and density take a back seat to endurance and retention, and here EEPROM is the preferred form of non-volatile memory.

The processes used to manufacture EEPROM are much more suited to withstanding harsh environments, which is particularly evident in ON Semiconductor’s family of AECQ-100 Grade 1 and Grade 0 EEPROMs. The flagship devices in this portfolio are the NV25080, NV25160, NV25320 and NV25640, which are true Grade 0 EEPROMs offering 8, 16, 32 and 65 kbit densities respectively.

As the automotive industry’s only true Grade 0 EEPROMs available today, they offer an endurance of 4 million read/write cycles, which is four times more than the equivalent Grade 1 parts from ON Semiconductor, and data retention of 200 years. They also feature error code correction, implemented in hardware and applied to each byte of data stored. As data are written the device automatically generates and stores a corresponding 3-bit code. If any bit in the stored byte is corrupted it will be apparent by comparing it to the 3-bit code, at which point the device will automatically correct it. All of the error correction happens automatically and is transparent to the host processor. This level of error correction is available across the range of Grade 0 EEPROMs.

The Grade 1 parts also offer excellent endurance of 1 million cycles and data retention of 100 years, but come with the added benefit of a lower 1.8V supply voltage, which is becoming increasingly important in a number of automotive applications. They also implement error correction in devices up to 64 kbyte, which is applied to every nibble (4-bits) of data stored.

More of the features we rely on in our cars are now considered safety-critical, which means they must meet even more demanding requirements. In this class of application, Flash memory is not acceptable, with the availability of Grade 1 and true Grade 0 EEPROM, automotive OEMs have access to the type of non-volatile memory they need to enable next-generation features.