Reliable communication in industrial control panels is the backbone of operational efficiency and innovation in both smart buildings and factory automation. As technology progresses, the landscape of wired connectivity undergoes a transformation with the advent of 10BASE-T1S Ethernet. This innovative standard replaces legacy fieldbus technologies, offering multiple benefits for modern networking environments and especially for Factory 4.0. By seamlessly integrating diverse systems onto a single, unified network, 10BASE-T1S eliminates the need for cumbersome gateways. Its reduced cabling requirements not only contribute to a lighter and more agile network but also present cost-savings. With its ability to meet connectivity demands of Factory 4.0, 10BASE-T1S emerges as the wired connectivity of the future, establishing a foundation for Factory 5.0.

onsemi's portfolio of 10BASE-T1S Ethernet controllers are at the forefront of this progression, providing increased reliability and performance in demanding industrial environments. The NCN26010 (MAC/PHY) and NCN26000 (PHY) controllers are designed for industrial multi-point networks, helping to reduce in-cabinet wiring while increasing bandwidth. Let's explore how these advanced components improve in-cabinet connectivity in both environments.

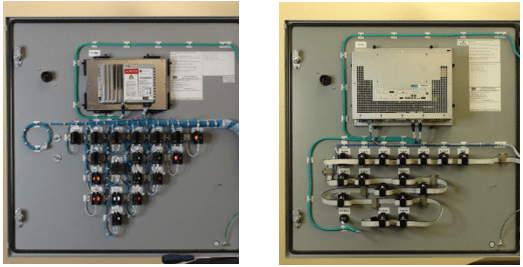

Reliable Connectivity in the Control Cabinet

Seamless communication between equipment and systems housed in-cabinet is critical to optimizing operations and productivity. onsemi's NCN26010 and NCN26000 devices excel in this regard, providing robust connectivity solutions tailored for in-cabinet and off-cabinet applications for shorter distances up to over 50 meters.

Improved Noise Immunity

Smart buildings and factories are difficult environments to maintain steady connectivity. Electromagnetic interference (EMI) and noise are common challenges in both smart buildings and factory automation. onsemi's proprietary Enhanced Noise Immunity (ENI) effectively mitigates these challenges by using advanced methods to reduce irradiance sensitivity. This ensures uninterrupted communication within control cabinet environments and increases their reliability.

Physical Layer Collision Avoidance (PLCA)

In-cabinet connectivity requires timely responsiveness, especially in factory automation. The physical layer collision avoidance (PLCA) reconciliation sub-layer within onsemi’s Ethernet controllers preemptively avoids collisions at the physical level and eliminates latency and overhead, which can be problematic for traditional collision detection mechanisms. This ensures a smooth and uninterrupted flow of data and supports real-time control and monitoring applications.

Streamlined Integration and Deployment

onsemi's NCN26010 MACPHY and NCN26000 PHY devices can be seamlessly integrated into new or existing Ethernet infrastructure, minimizing interruptions during installation. The compact form factor of these devices allows for flexible installation options within enclosures and optimizes space utilization.

Fostering Innovation and Efficiency

Reliable connectivity in the control cabinet lays the foundation for innovation and efficiency in smart buildings and factory automation. onsemi's ethernet controllers enable OEMs to leverage advanced technologies and drive transformative change. Whether it's optimizing building management systems or improving production processes, these components provide the robust connectivity needed to achieve new levels of efficiency.

While the NCN26010 (MAC/PHY) controller is suitable for realizing a cost-effective and extremely compact end node together with low-cost MCUs, the new NCN26000 PHY device complements onsemi's 10BASE-T1S portfolio by supporting infrastructure and more complex devices (FPGA or SoC-based) with an MII interface that connects to Clause 4 compliant media access controllers (MAC). Among other things, this enables the realization of 10BASE-T1S switches together with low to medium complex FPGAs. The 10 Mbit/s half-duplex bus wiring also reduces wiring effort and costs and has a significant impact on simplified maintainability.

onsemi's NCN26010 MACPHY and NCN26000 PHY devices are redefining connectivity across smart buildings and factory automation. Prioritizing reliability, efficiency and scalability, these state-of-the-art components enable seamless communication and integration of devices and systems into enclosures, driving innovation and efficiency across industrial and cloud applications. With onsemi's advanced technology at the forefront, the connectivity needs of Factory 4.0 are easily supported and the conditions are established to usher in the next generation of industrial advancements in Factory 5.0.

Learn more about the NCN26010 and the NCN26000 or download our whitepaper for a deep dive into 10BASE-T1S.

Additional Resources