すべては18年前、私が最初のバックカメラ(RVC)用の車載用CMOSイメージセンサの1つに取り組んだことから始まりました。当時、RVCを装備した車は運転者が車の後方を確認できるため、素晴らしい大発明でした。それから20年後、RVCは標準部品となり、さらに多くのカメラが現代の自動車の先進運転支援システム(ADAS)の基礎を築いています。私のキャリアも当時のMicron Technology社からAptina社、そして現在の オンセミへと移行しましたが、ADASシステムも同様に大きな変化を遂げてきました。

それが今日では、さらに高度な車両システムが、近くの物体や死角にある車の検知、車線からの逸脱、ハイウェイ走行での速度と距離の維持などの状況で運転者に警告を発します。こうした身近な安全機能の多くは、車載用イメージセンサによって実現されます。この交通革命の一翼を担えることは、私個人にとってもかけがえのない経験です。私はオンセミチームの一員として、現在では業界標準となった数々の画期的な機能を、業界で初めてもたらす機会に恵まれました。例えば、現在多くのセンサ設計で採用されているデュアルゲインピクセル技術やハイダイナミックレンジ(HDR)技術はオンセミが導入しました。ADASシステムの大部分に、 オンセミが開発したイメージセンサが使用されていると胸を張って言えます。

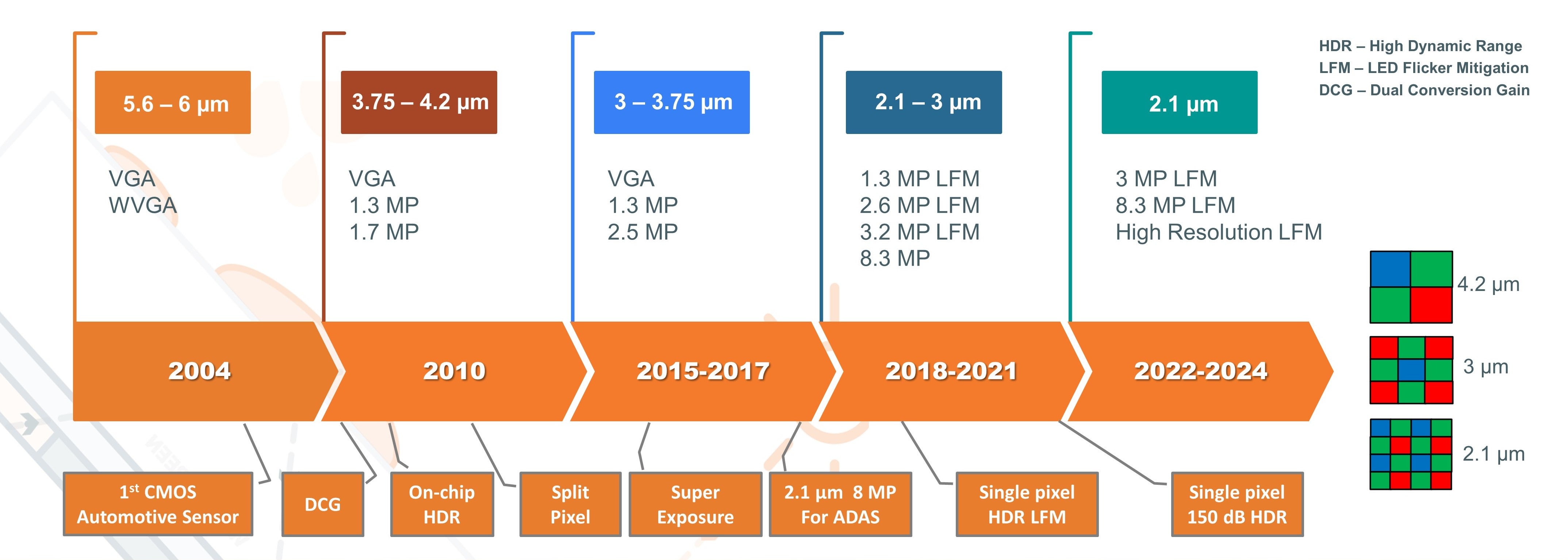

画像センシング技術の進化は、私のキャリアを通じて劇的に変化してきました。私は車載用イメージセンサの目覚ましい進歩を目の当たりにしてきました。

解像度

画像の解像度は、画質に関する重要なパラメータの1つです。解像度が高いほど、特に自動車の景色の場合、エッジがシャープになり、ディテールが細かく表現されます。ビデオグラフィックアレイ(VGA)センサが登場したとき、0.3メガピクセル(MP、640 H x 480 V)の画像しか生成できなかったことを想像してみてください。オンセミの AR0820AT は、市場初の8.3MP(3840 H x 2160 V)の車載グレードのイメージセンサです。高解像度なので、複数のアプリケーション(表示やセンシングなど)に対応でき、1台のカメラでより優れた物体検出が可能になります。安全上重要な意思決定を可能にすべく、多くの車載用アプリケーションは大容量の画像データを必要としており、近い将来、市場はさらに高い解像度を求める傾向にあることがわかります。

ピクセルサイズ

ピクセルサイズも、速度、感度、画質の理想的なバランスを持つセンサを選択するための要素です。ピクセルが大きければ、利用可能な光を集める面積が増えますが、それが必ずしも画質の向上につながるわけではありません。ピクセルサイズが大きいセンサよりも、同一の光学領域をカバーするピクセルサイズが小さいセンサが優れた性能を発揮することがあります。

オンセミのHyperluxファミリは、低照度、全信号対雑音比 (SNR)、HDRといった代表的な車載条件において、2.1µmピクセルセンサが3µmピクセルセンサより優れた性能を発揮する例です。さらに高度なイメージセンサを追及する過程で、ピクセルサイズは6µmから現在の2.1µm超露光ピクセルに縮小され、同時に性能も向上しています。

露出HDR技術

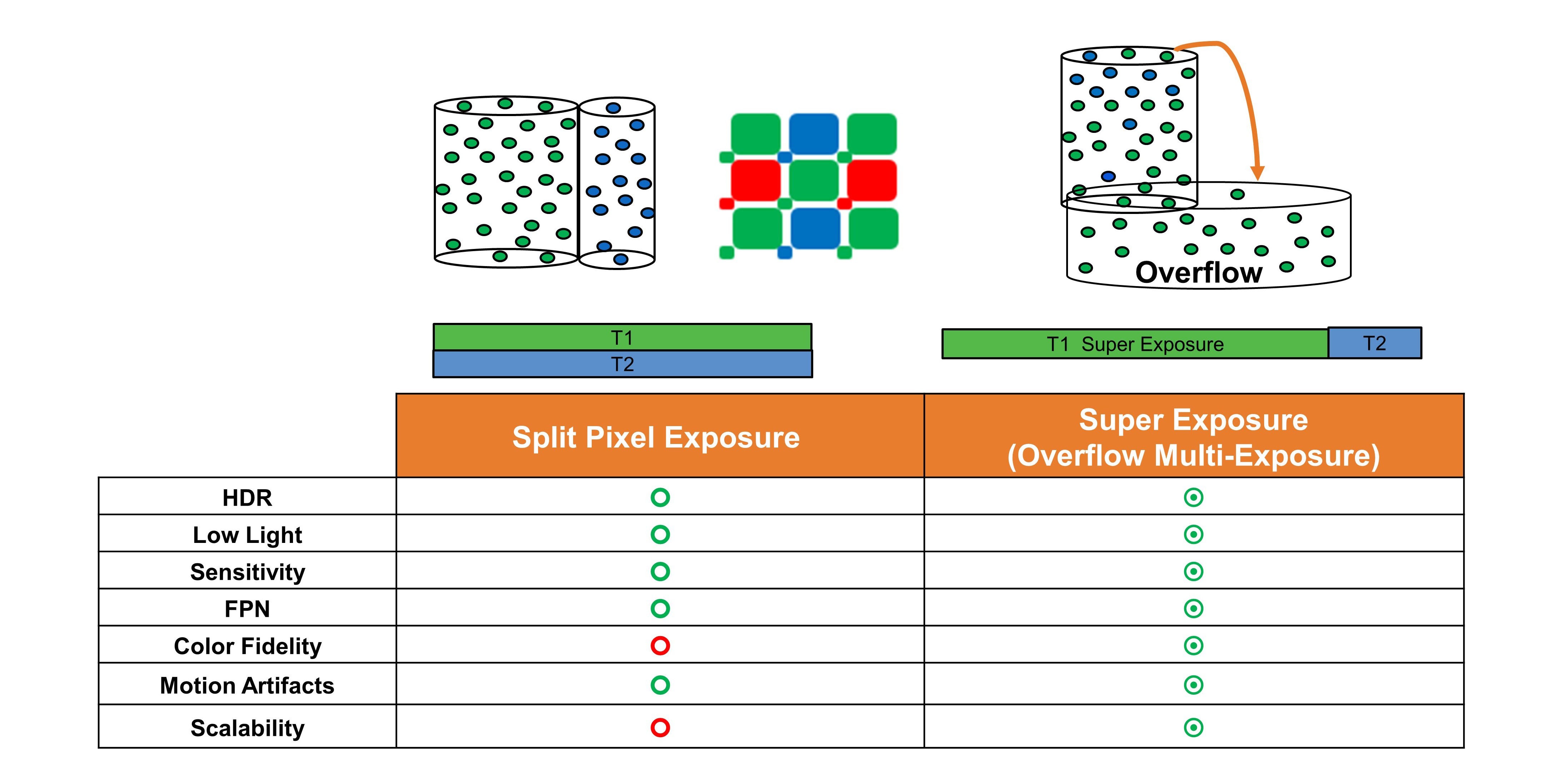

オンセミは、大小のサブピクセルに基づいてHDR画像を生成するスプリットピクセル技術を発明した最初の企業です。スプリットピクセル・アプローチでは、単一ピクセル専用のセンサ領域が2つの部分に分割され、大部分の領域を大きなフォトダイオードがカバーし、小さなフォトダイオードが残りの部分を使用します。しかし、画質の劣化、暗部ノイズの増加、特に高温時の性能低下という欠点があるため、スプリットピクセルの使用を終了しました。

これらの欠点に対する私たちの解決策は、オーバーフロー多重露光としても知られているスーパーエクスポージャー技術です。この技術では、大きな信号または電荷がオーバーフローできる領域をピクセルに追加します。この方法は雨粒をバケツで受けるようなものですが、バケツから溢れた雨粒も保てるように、大きなたらいを用意しています。この「バケツ」の信号は非常に高い精度で容易に読み取れるため、低照度でも優れた性能を発揮します。また、この「たらい」には溢れたものがすべて入るので、ダイナミックレンジが拡張され、明るいオブジェクトやシーンを実際の色でキャプチャすることができます。そのため、明るい条件でも飽和することなく、低照度条件に対してピクセル領域全体が使用されます。その結果、スーパーエクスポージャー技術は、車載アプリケーションのハイダイナミックレンジのシーンで、点滅するLEDライトおよび標識の色やディテールをすべてキャプチャできる機能と併せて、より優れた画質を実現します。

ダイナミックレンジ

ダイナミックレンジとは、シーンの中で最も明るい部分と最も暗い部分の比率のことです。オンセミのイメージセンサは最初に120dB、その後140dB HDRを達成しました。Hayabusaファミリは、LEDフリッカー抑制(LFM)センサを搭載した市場初の120dB HDRです。つい最近、私たちが発表したHyperluxイメージセンサファミリは、150dB HDR LFMという業界をリードする性能を持ち、画質も向上しました。AR0823AT 8.3MPセンサと AR0341AT 3MPセンサは、Hyperlux技術を採用した最初のセンサです。この素晴らしいHDRにより、Hyperluxは鮮やかな色彩、シャープネス、そして温度や照明条件に左右されず高度な予測が可能な動作によって、さらに安全性の高い設計の基となる画質を提供します。Hyperluxイメージセンサは、図3のように、最も要求の厳しい状況やコーナー条件でもはるかに優れた視認性を発揮します。

車載カメラシステムは、道路上のさまざまな物体の色、形、サイズを識別できる唯一のセンシングモダリティなので、能動的安全の重要な要素です。旅の各中間地点で、オンセミチームは低照度、HDR、画質、シャープネスの新たなベンチマークを確立するために熱心に取り組みました。このように、自動車メーカーは初期のRVCをレベル2で動作する車両システムへと移行させ、現在では自動運転のレベル2+およびレベル3を積極的に導入しています。業界をリードする性能と機能を備えたHyperluxイメージセンサは、システム開発コストを削減しながら、安全指標を改善し、より高速での自律走行を可能にする態勢を整えています。多くの自動車メーカーやティア1企業が、ADASカメラの設計に オンセミ のイメージセンサを選択したのは驚くことではありません。

より安全でより良い未来への道は、ここで終わりません。より高いレベルの交通安全と自動運転を目指して、一緒に旅を続けましょう。

Hyperluxイメージセンサ・ファミリの詳細については、こちらをご覧ください。